Vehicle Dynamics Laboratory

- Home

- Faculty of Engineering & Technology

- Department of Automobile Engineering

- Vehicle Dynamics Laboratory

Vehicle Dynamics Laboratory

Vehicle Dynamics involves the study of the motion of vehicles, the interaction of the vehicle with its surroundings, the influence of forces on vehicles and the response behaviour of vehicles to different road conditions. The complexity of the input and output parameters for vehicle motion is analyzed, and a solution is arrived at. The fundamental concepts derived from the dynamics of machines and systems coupled with the control logic of such systems form the foundation of the subject. Thus, Vehicle Dynamics requires an interdisciplinary approach to solving vehicle motion problems and arriving at solutions.

SRM Institute of Science and Technology is one of the few Higher Education Institutions in India to have a dedicated lab for Vehicle Dynamics with research-oriented Faculty Members.

Research Team:

- A.J.D. Nanthakumar, Assistant Professor, Department of Automobile Engineering, SRMIST

- K. Kamalakkannan, Associate Professor, Department of Automobile Engineering, SRMIST.

- S. Yokeshwaran, Assistant Professor, Department of Automobile Engineering, SRMIST.

Specifications

The vibration signature of a dynamic system is the characteristic pattern of vibration it generates while it is in operation. It has been shown many times over that the vibration of an operating system provides far more information about the inner workings of that system than any other type of nondestructive test.

The lab is equipped with a vibration analysis setup with the following kits:

- 4 channel DAQ With FFT analysis

- Complete Modal software, using Hammer, accelerometer, and Shaker free run, Geometry creation, and direct FRF with Damping

- Tri-Axial IEPE Accelerometer, Tapped Base, 500g range

- Miniature Piezo-Tronic IEPE Accelerometer,50g range

- Impact Hammer 2000N range,Sensitivity-2.5mV/N

- Microphone - 1/2" prepolarized, IEC61672 Class 1, 6.3Hz ~ 20kHz frequency range, free-field

- Bungee Shock cord - for hanging Model testing of Component weight up to 100Kg.

- Fixture for Free and Forced Vibration,1/2 m cantilever beam

Apollo Tyres has donated a dedicated tire model setup. The students are taught about the construction and working of tires. The influence of tires on the dynamic behavior of the vehicle is also analyzed.

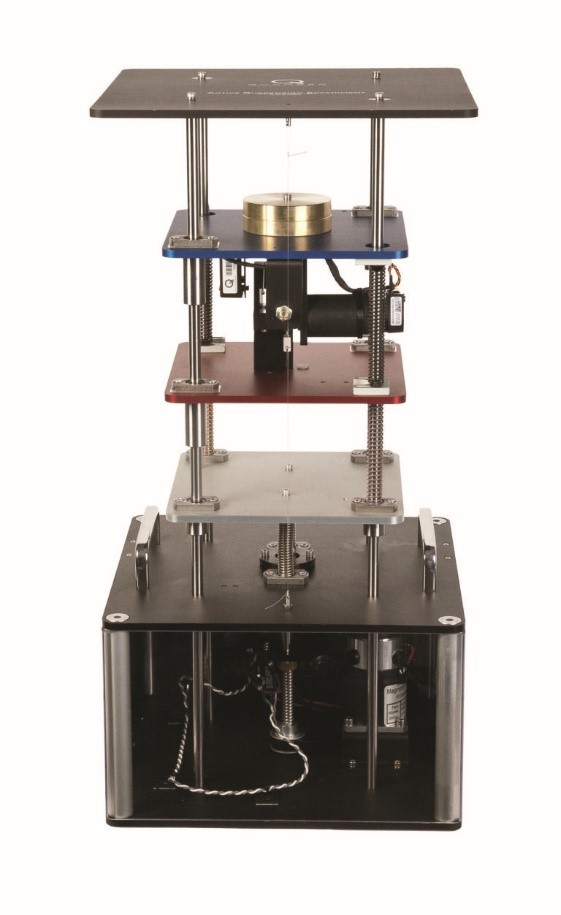

Active suspension technology is used in the automotive industry to continuously control the vertical movement of the vehicle wheel using an actively controlled actuator placed on the suspension axis. Students can tune the supplied controller or design their own controllers to optimise the various suspension performance parameters, which include:

- Ride Comfort: This is related to the vehicle body motion sensed by the passengers. It can be measured using either the accelerometer that is mounted on the top plate or the encoder (for a direct position measurement).

- Suspension Travel - refers to the relative displacement between the vehicle body and the tyre that is limited to a certain range of motion. This can be measured using the suspension encoder that is mounted on the capstan.

- Road handling is associated with the contact forces between the road surface and the vehicle tyres and depends on tyre deflection. Tyre deflection is the relative displacement between the tyre and the road, and it can be measured using all the encoders.

The damping force of a shock absorber determines the ride comfort and stability of a vehicle. Thus, the study of force characteristics of shock absorbers is essential. Static and dynamic tests can be performed to evaluate the tension/compression properties of the shock absorbers. The Damper Testing machine specifications are given below:

- Velocity 0.52 m/sec, Force 1 Ton, Stroke 100 mm, Variable cam mechanism, A.C Motor.

- NI DAQ with 4 Analog inputs, 2 Analog outputs, Load cell with an amplifier, LVDT, A.C Drive.

- Lab view-based application for data monitoring, data logging, and reporting.

Virtual test driving is the norm of the day, and this test method can be used to master the current requirements of vehicle development. In accordance with the automotive systems engineering approach, virtual test driving can be used to develop and test systems and system networks in their entirety within the whole vehicle in realistic scenarios. Carmaker software is used in the industry for specifically testing passenger cars and light-duty vehicles. Using Carmaker software, one can accurately model real-world test scenarios, including the entire surrounding environment, in the virtual world. The powerful and real-time-capable models for vehicles, roads, drivers, and traffic make this possible. Carmaker is an open integration and test platform that can be applied throughout the entire development process, from model to software to hardware to vehicle-in-the-loop. Carmaker's impressive performance guarantees flexibility, productivity, and precision for all simulation tasks, thereby ensuring significant savings in cost and time for the development of your vehicle.

The Vehicle Dynamics lab is equipped with 30 licences of the Car Maker software. The students receive training in the virtual testing of vehicles through the software. Students can create driver models, detailed vehicle models, and road and traffic models.

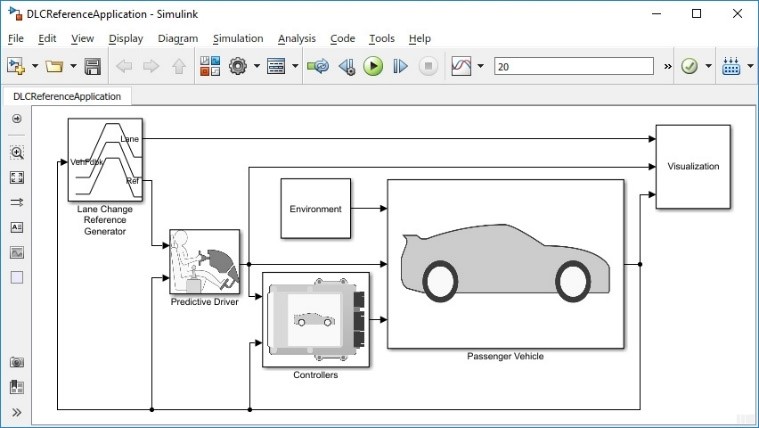

Simulink provides a standard model architecture that can be used throughout the vehicle development process. It supports ride and handling analyses, chassis control development, software integration testing, and hardware-in-the-loop testing. By integrating vehicle dynamics models with a 3D environment, one can test ADAS and automated driving perception, planning, and control software. These models let us test your vehicle with standard driving manoeuvres such as a double lane change or with our own custom scenarios.

The Vehicle Dynamics lab is equipped with 35 licenses of the MATLAB and SIMULINK software.

Powerful productivity and expandability with expandable tower and small form factor desktops with mission-critical features.

Processor: Intel i7 – processor quad-core with 8 threads processor

RAM: 8 GB

Display: NVIDIA GT 730 2 GB graphics card

Hard Disk: 1 TB 7200 rpm

Additional facilities include Conference Table with a Full HD EPSON projector for conducting training sessions and conference presentations.

The students a have imparted training in the following domains:

- Tire mechanics

- Longitudinal dynamics

- Lateral dynamics

- Vertical dynamics

- Control system design and implementation in Vehicle Dynamics

- Design and Fabrication of Magnetorheological damper:

A semi-active suspension using a magnetorheological damper is studied. Various designs of magnetorheological dampers have been fabricated and characterised. The controllers for magnetorheological dampers have been formulated and implemented in vehicle dynamic models.

- Road profile modelling for vehicle dynamic simulations:

The smoothness or roughness of the road pavement determines the comfort of the passengers occupying a vehicle travelling on highways. In addition to the passenger comfort, the cost of transport also depends on the smoothness of the road profile, as the energy involved in rolling the tyres and thereby moving the vehicle depends on the smoothness factor of the road. The road smoothness directly affects the fuel consumption of the vehicle and the wear and tear of the vehicle system and its subassemblies. In this direction, various road profiles and their mathematical models have been analysed, including ISO 8608, two split models, the Gillespie model, the BSI model, etc.

- Noise Vibration and Harshness (NVH) control in vehicular systems:

Higher levels of sound and vibration pose an immediate comfort as well as a health hazard for humans travelling in automobiles. Nodal government agencies and health institutions have suggested the time and level of sound and vibration regulations that the human body can tolerate. These regulations are becoming more

And stricter, wherefore new methods for sound and vibration attenuation are always in demand. Various methodologies for NVH control and improving passenger ride comfort have been analysed, and new strategies have been proposed.

- Simulation of vehicle dynamic systems:

The lab is equipped with vehicle dynamic analysis software that includes the Vehicle Dynamics block set of the Simulink module and Car Maker virtual analysis software. The Vehicle Dynamics research team periodically reviews and discusses with industrial partners to provide simulation solutions in the domain of vehicle dynamics.

- CFD analysis of shock absorber dampers:

The performance of automotive dampers is dependent on the fluid characteristics and damper orifice characteristics. Current research is going on in the design and analysis of automotive dampers with respect to the rheological characteristics of the working fluid of the damper and the design of dampers based on the rheological behaviour of the working fluid.

Laboratory In-Charge

Dr. A. J. D. Nanthakumar