Tribology and Surface Interaction Research Lab

- Home

- Faculty of Engineering & Technology

- Department of Mechanical Engineering

- Tribology and Surface Interaction Research Lab

Tribology Lab

This laboratory aims at developing and improving the technologies and products in engineering applications. In our laboratory we undergo in-depth study in the domains of friction, wear and lubrication and explore the science behind these phenomenons.

Specifications

- Investigating the frictional Properties of Steel on Steel using Tribo pairs – Dry test

- Investigating the frictional Properties of Brass on Steel using Tribo pairs – Dry test

- Investigating the frictional Properties of copper on Steel using Tribo pairs – Dry test

- Investigating the Wear characteristics of Copper on steel of Tribo pairs in wet Condition

- Investigating the Wear characteristics of Brass on steel of Tribo pairs in wet Condition

- Investigate the Anti wear Properties of Lubricants using Four Ball Tribometer- Engine oil

- Investigate the Anti wear Properties of Lubricants using Four Ball Tribometer- Vegetable oil

- Investigate the Rolling contact fatigue of bearing steel using Four Ball Tribometer using gear oil at ambient temperature

- Investigate the Rolling contact fatigue of bearing steel using Four Ball Tribometer using Vegetable oil at 75-degree Temperature

- Investigate the Extreme Pressure properties given lubricant using Four Ball Tribometer

- Investigate the load carrying capacity of given lubricant mineral oil and castor oil using Brugger test

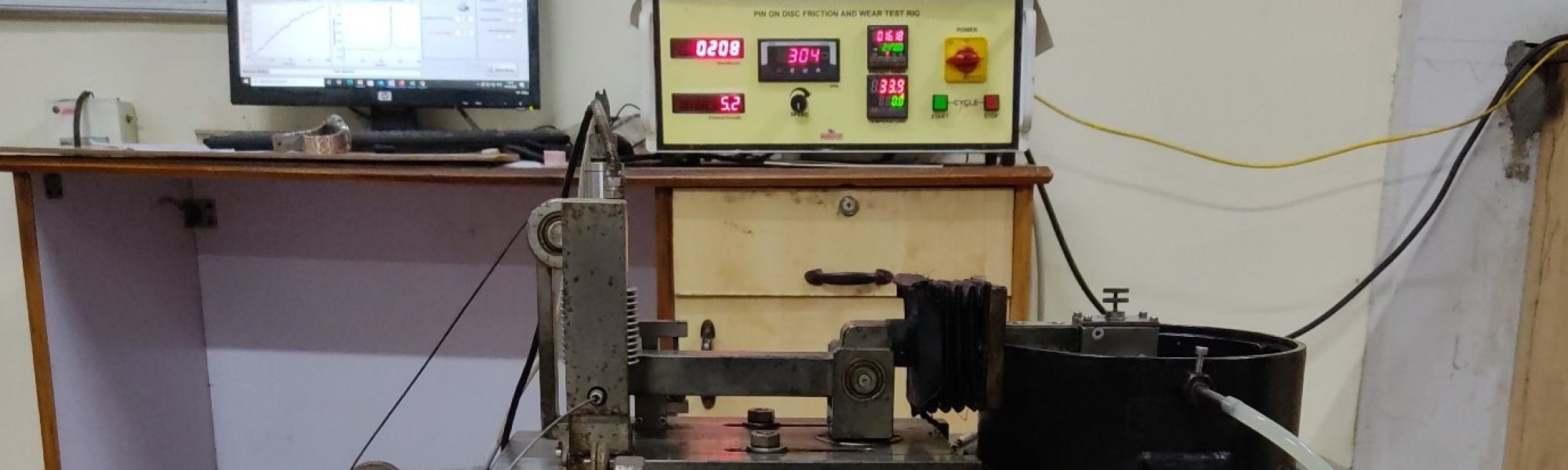

This is used to evaluate the tribological properties of bulk materials, coatings, etc. under lubricated condition. The normal load can be varied from 10 N to 200 N. The pin diameter, pin length and wear track radius can be varied from 8 mm to 10 mm, 30 mm to 40 mm and 50 mm to 145 mm, respectively.

This tribometer is useful to evaluate the tribological properties of bulk materials, coatings, etc. under dry condition. The normal load can be varied from 5 N to 100 N. The pin diameter, pin length and wear track radius can be varied from 8 mm to 10 mm, 30 mm to 30 mm and 50 mm to 100 mm, respectively.

The performance of lubricants is determined by using a four ball tribometer. The normal load can be varied from 60 N to 8000 N. The ball diameter is 12.7 mm diameter. The extreme pressure and anti-wear properties can also be determined by this equipment.

This gear test rig is used to study the scuffing resistivity of lubricants. It was fabricated by students of Department of Mechanical Engineering. Its design is based on the AGMA Tribology test report by W.A Bradley. The gear and pinion teeth are 30 and 20 in number, and the pitch circle diameters are 108 mm and 72 mm, respectively

Frequency : 20KHz, Probe Diameter:12mm and 20mm

Technical Specification

- Make: Wagner

- Specimen diameter :10mm

- Specimen length: 14mm

- Speed motor:1400rpm

- Max weight: 25kg

| Title of project | Duration | Funding Agency | Grant | Investigators | Status |

| Tribological investigations of nanoparticles added vegetable oils | 2017-2018 | SRMIST Selective Excellence Project | INR 3.25 lakhs | Shubrajit Bhaumik | Completed |

| Surface Texturing of steel to reduce friction | 2019-2020 | Tata Steel | INR 3.00 lakhs | Shubrajit Bhaumik and Dr.Shubhabrata Datta | Ongoing |

| Tribological and rolling contact fatigue analysis of AISI 52100 steel under nano lubricated condition | 2019-2022 | DST-SERB (TARE) | INR 18.30 lakhs | Shubrajit Bhaumik and Dr.M.Kamaraj, IIT Madras | Ongoing |

Peer Reviewed Journals (SCI/Scopus Index)

2018

- Shubrajit Bhaumik, Rishabh Maggirwar, Shubhabrata Datta, S.D Pathak, “Analyses of anti-wear properties of castor oil with zinc oxide nano friction modifiers, Applied Surface Science, Vol. 48, 277-286.

- Anuj Kumar Sharma, Jitendra Kumar Katiyar, Shubrajit Bhaumik, Sandipan Roy, “Influence of alumina/MWCNT hybrid nanoparticle additives on tribological properties of lubricants in turning operations”, Friction, https://doi.org/10.1007/s4054.

- A. Senatore, TVVLN Rao, “Partial Slip Texture Slider and Journal Bearing Lubricated With Newtonian Fluids: A Review”, ASME Journal of tribology, Vol.140(4):040801-040801-20.

- Vinay Kumar Patel, Shivani Chauhan, Jitendra K Katiyar, “Physico-mechanical and wear properties of novel sustainable sour-weed fiber reinforced polyester composites”, Materials Research Express, Vol. 5 (4), 045310.

- Jitendra K Katiyar, Anuj Kumar Shrama and Basant Pandey “Synthesis of Iron-Copper Alloy using Electrical Discharge Machining (EDM)”, Materials and Manufacturing Process. (DOI: 10.1080/10426914.2018.1424997).

2017

- Neeraj Kumar, Shubrajit Bhaumik, Arijit Sen, Pooja Shukla, S.D Pathak, 2017, “One-pot synthesis and first-principles elasticity analysis of polymorphic MnO2 nanorods for tribological assessment as friction modifiers”, RSC Advances, Vol. 7, 34138-34148.

- Shubrajit Bhaumik, Shubhabrata Datta, S.D Pathak, “Analyses of tribological properties of castor oil with various carbonaceous micro- and nano- friction modifiers”, ASME Journal of Tribology. doi:10.1115/1.4036379.

- Shubrajit Bhaumik and S.D pathak, 2017, “Effect of Nano and Micro Friction Modifier Based Lubricants on Wear behavior between Steel-Steel Contacts”, Tribology in Industry, Vol. 39(1), 136- 143.

- Jitendra K Katiyar, Sujeet K Sinha and Arvind Kumar, “Lubrication Mechanism of SU-8/Talc/PFPE Composite”, Tribology Letters (doi:10.1007/s11249-017-0863-3)

- Sharma, A.K., Tiwari, A.K., Dixit, A.R., Singh, R.K. Temperature distribution over cutting tool with Alumina-MWCNT hybrid nanoparticle enriched cutting fluids in hard turning using computational fluid dynamics (CFD) analysis. International Journal of Thermal Sciences. (Under review).

- Sharma, A.K., Tiwari, A.K., Dixit, A.R., Singh, R.K. “Measurement of Machining Forces and Surface Roughness in Hard Turning of AISI 304 steel using Alumina-MWCNT Hybrid Nanoparticles Enriched Cutting Fluid”, Measurement.. (Under review)

- Sharma, A.K., Tiwari, A.K., Dixit, A.R., Singh, R.K. Novel uses of alumina-MoS2 Hybrid Nanoparticle Enriched Cutting Fluid in Hard Turning of AISI 304 steel. Journal of Manufacturing Processes. (Under review).

- Singh, R.K., Dixit, A.R, Mandal, A., Sharma, A.K. Emerging application of nanoparticle enrich cutting fluid in metal removal processes. Journal of the Brazilian Society of Mechanical Sciences and Engineering. DOI:https://doi.org/10.1007/s40430-017-0839-0.

- Singh, R.K., Sharma, A.K., Dixit, A.R, Tiwari, A.K., Pramanik, A., Mandal, A. Performance Evaluation of Alumina-graphene Hybrid Nano-cutting Fluid in Hard Turning. Journal of Cleaner Production. doi:10.1016/j.jclepro.2017.06.104.

2016

- Shubrajit Bhaumik and S.D Pathak,2016, “A comparative experimental analysis of tribological properties between commercial mineral oil and neat castor oil using Taguchi method in boundary lubrication regime”, Tribology in Industry,Vol. 38(1), 33-44.

- Jitendra K Katiyar, Sujeet K Sinha and Arvind Kumar, “In-situ Lubrication of SU-8/Talc Composite with Base Oil (SN150) and Perfluoropolyether”, Tribology Letters (doi:10.1007/s11249-016-0736-1)

- Anand Singh Rathaur, Jitendra K Katiyar, Bikas Prasad and Sanjeev Kumar, “Enhancement of Mechanical and Metallurgical Performance of SS Joint using Weld Bonds”, International Journal of Mechanical & Mechatronics Engineering IJMME-IJENS, Vol. 16 No. 3 (2016) pp 112-121.

- Jitendra K Katiyar, Sujeet K Sinha and Arvind Kumar, “Friction and Wear Durability study of SU-8 Composites with Talc and Graphite as Fillers”, Wear, Vol. 362-363 (2016) pp 199-208.

- Megha Verma, Jitendra K Katiyar and K. C. Yadav, “Enhancement of Mechanical And tribological Properties of SU-8 Polymer using Graphene Filler”, International Journal of Scientific & Engineering Research, Vol. 7, Issue 2 (2016) pp 1206-1211.

- Jitendra K Katiyar, Sujeet K Sinha and Arvind Kumar, “Effect of Graphite Concentration on the Tribological and Mechanical Properties of filled SU-8”, Tribology Online, Vol. 11, No.2 (2016) pp 152-158.

- Jitendra K Katiyar, Sujeet K Sinha and Arvind Kumar, “Effects of Carbon Fillers on the Tribological and Mechanical Properties of an Epoxy Based polymer (SU-8)”, Tribology – Materials, Surfaces & Interfaces, Vol. 10, No.1 (2016) pp 33-44.

- Sharma, A.K., Tiwari, A.K., Dixit, A.R. “Rheological Behaviour of Nanofluids: A Review” Renewable & Sustainable Energy Reviews, 53, 779-791.

- Sharma, A.K., Tiwari, A.K., Dixit, A.R. “Effects of Minimum Quantity Lubrication (MQL) in machining processes using conventional and nanofluid based cutting fluids: A comprehensive review”, Journal of Cleaner Production, 127, 1-18.

2015

- Shubrajit Bhaumik,S.D Pathak,2015, “Analysis of anti-wear properties of CuO nanoparticles as friction modifiers in mineral oil (460 cSt viscosity) using pin-on-disk tribometer”, Tribology in Industry, Vol. 37(2), 196-203.

- Sharma, A.K., Tiwari, A.K., Dixit, A.R. “Progress of nanofluid application in machining: A review”, Materials and Manufacturing Processes, 2015, 30(7) pp. 813-828.

2014

- Shubrajit Bhaumik, S.Prabhu, Kingsly Jeba Singh, “Analysis of tribological behavior of carbon nano tube based industrial mineral gear oil 250 cSt viscosity”, Advances in Tribology,Vol. Ariticle ID 341365 .

International/National Conferences

2017

- Shubrajit Bhaumik, Rajat Taneja, Shashank Malla, “ Experimental analsyis of anti-wear properties of friction dust based aluminium composite using pin on disc apparatus”, National Conference on Advances in Mechanical Sciences, C. Abdul Hakeem College of Engineering and Technology, Melvisharam, Tamil Nadu 632509.

- Shubrajit Bhaumik, Shubhabrata Datta , S.D Pathak , Rishab Maggirwar , Atharva Kadam, Analyses Of Antiwear And Extreme Pressure Properties Of Zinc Oxide Nano Friction Modifiers Based Vegetable Oil, International Conference on Nanoscience and Nanotechnology, SRM University, August 9-11.

- Shubrajit Bhaumik, Shubhabrata Datta , S.D Pathak , Investigation of tribological properties of zinc oxide nano particles based castor oil between steel contacts, International Conference on Industrial Tribology, Tribology Society of India, Kolkata, 6-9th December.(Accepted for presentation)

- Jitendra K Katiyar, Sujeet K Sinha and Arvind Kumar, “Effect of Perfluoropolyether (PFPE) Concentration on the Tribological and Mechanical Properties of filled SU-8/Talc Composite”, Proceedings of 6th World Tribology Congress, Beijing (China) September 17-22, 2017. (Accepted for Presentation)

- Jitendra K Katiyar and Shubrajit Bhaumik, “Performance Analysis of SU-8 and Its Composite Coatings on Bearing Steel”, 9th International Conference on Industrial Tribology(ICIT-2017), Vedic Village Resort in Kolkata from 6th -9th December. (Accepted for Presentation)

- Sharma, A.K., Tiwari, A.K., Dixit, A.R., Singh, R.K., “Investigation into Performance of SiO2 Nanoparticle Based Cutting Fluid in Machining Process”. Materials Today: Proceedings, 4, pp. 133-141.

2016

- Shubrajit Bhaumik, S.D Pathak, Abhishek Kumar, Sahil A M and Dheeraj Kumar, “A study on tribological behavior of bio degradable castor oil using pin on disc tribometer” , Proceedings of the International Conference on Materials, Design and Manufacturing Process, February 17-19, College of Engineering Guindy, Anna University, Chennai, India.

- Sharma, A.K., Singh, R.K., Tiwari, A.K., Dixit, A.R., “Characterization and Experimental investigation of Al2O3 based nanocutting fluid in turning of AISI1040 steel under minimum quantity lubrication (MQL)”. Materials Today: Proceedings, 3, pp. 1899–1906).

- Sharma, A.K., Singh, R.K., Tiwari, A.K., Dixit, A.R., “Tribological investigation of TiO2 based nanocutting fluid in machining under minimum quantity lubrication (MQL)”. Materials Today: Proceedings, 3, pp. 2155–2162.

- Sharma, A.K., Tiwari, A.K., Dixit, A.R., “Characterization of TiO2, SiO2 and Al2O3 nanoparticle based cutting fluids”. Materials Today: Proceedings, 3, pp. 1890–1898.

- Singh, R.K., Sharma, A.K., Dixit, A.R, Tiwari, A.K. “Experimental investigation on thermal conductivity and specific heat of nano particles mixed cutting fluids”. ICAAMM-2016, Hyderabad. India 7-9 July 2016.

2015

- Shubrajit Bhaumik, S.D Pathak, “Experimental analysis of antiwear property of 460cSt Industrial mineral gear oil with macro and nano particles using pin-on-disc apparatus”, Malaysian International Tribology Conference, Penang, 16th – 17th November.

- Jitendra K Katiyar, Sujeet K Sinha and Arvind Kumar, “Enhancement of Tribological Performance of Bearing Steel by Polymer Coating”, Proceedings of 6th International and 27th All India Manufacturing Technology, Design and Research (AIMTDR) Conference, College of Engineering, Pune (India), December 16-18, pp 2047-2049.

- Jitendra K Katiyar, Sujeet K Sinha and Arvind Kumar, “The Effect of Sliding Speed on Fabricated SU-8/Talc/PFPE Composites”, NTC16, IIT BHU, Varanasi (India), December 08-10.

- Megha Verma, Jitendra K Katiyar and R. K. Gupta, “Improvement of Tribological and Mechanical Performance of SU-8 by Boron Nitride as Filler”, 6th International and 27th All India Manufacturing Technology, Design and Research (AIMTDR) Conference College of Engineering, Pune (India), December 16-18, pp 2102-2105.

- Vimal Kumar, Pratima Verma, Onkar, Suraj Pratap Singh, Jitendra Katiyar, “Facility and Process Layout Analysis of a SME using Simulation: A Case Study of a Manufacturing Company”, Proceedings of the 2016 International Conference on Industrial Engineering and Operations Management, Kuala Lumpur (Malaysia), March 8-10.

- Sharma, A.K., Tiwari, A.K., Dixit, A.R., “Mechanism of Nanoparticles functioning and Effects in Machining Processes: A Review”. Materials Today: Proceedings, 2, pp. 3539 – 3544.

- Sharma, A.K., Tiwari, A.K., Dixit, A.R., “Improved Machining Performance with Nanoparticle Enriched Cutting Fluids under Minimum Quantity Lubrication (MQL) Technique- A Review”. Materials Today: Proceedings, 2, pp. 3545 – 3551.

- Jitendra K Katiyar, Sujeet K Sinha and Arvind Kumar, “Effect of Graphite Concentration on the Tribological and Mechanical Properties of filled SU-8”, International Tribology Conference, Tokyo University of Science, Tokyo (Japan), September 16-20, 2015, pp 657-658.

2014

- Shubrajit Bhaumik, S. Prabhu, “Carbon Nano Tube – a new generation nano additive for lubricants”, Paper Id TSI914503, 18th February 2014, ASIATRIB ,Tribological Society of India, Agra, India.

- Shubrajit Bhaumik, S.D Pathak,2014,“Analysis of anti-wear property of Copper Oxide nanoparticles based mineral gear oil 460cSt viscosity using pin-on-disk tribometer”, International Symposium for Research Scholars, IIT Chennai.

- Jitendra K Katiyar, Sujeet K Sinha and Arvind Kumar, “The Effect of Filler Materials on Mechanical and Tribological Properties of SU-8”, NTC14, PES University Bangalore (India), December 15-17.

- Jitendra K Katiyar, “Novel Synthesis of Micro- & Nano- Granular Fe-Cu Alloy by Electric Discharge Machining”, IITK Student Research Convention, IIT Kanpur (India), August 9-10.

- Jitendra K Katiyar and Sujeet K Sinha, “Surface Micromechanical & Tribological Properties of Different Coating on Glass Substrate”, ASIATRIB International Conference, Agra (India), February 17-20.

2013

- Shubrajit Bhaumik, Varun Karpurapu , Nihit Upala, “Load bearing capacity of CNT based nano lubricant “, 3rd National Conference on Emerging trends in CAD/CAM/CIM, PSG College of Technology ,Coimbatore.

- Shubrajit Bhaumik, R. G. Padmanabhan, “Tribological behavior of MWCNT based synthetic oil”, ICEMAP, Tagore Engineering College, Chennai.

- Undergraduate: 15ME327E Industrial Tribology

- Post graduate: ME2114 Tribology in Design

- One Credit Course on Surface Engineering with India Pistons.

| Academic projects | |||

| Title of the project | Degree | Name of Supervisor(s) | Year |

| Experimental investigation of anti wear properties of various nano friction modifiers based vegetable oil | B.Tech Mechanical | Shubrajit Bhaumik | 2017 |

| Experimental investigation of anti wear properties of friction dust based aluminium composites using pin on disc | B.Tech Mechanical | Shubrajit Bhaumik | 2017 |

| Experimental analysis of tribological properties of castor oil with multi wall carbon nano tubes in boundary lubrication regime | B.Tech Mechanical | Shubrajit Bhaumik | 2016 |

| Experimental analysis of tribological behaviour of castor oil using pin on disc tribometer | B.Tech Mechanical | Shubrajit Bhaumik | 2015 |

| Experimental analysis of tribological behaviour of 460cSt Mineral oil using pin on disc tribometer | B.Tech Mechanical | S.D Pathak/ Shubrajit Bhaumik | 2015 |

| A study of EN 24 wear in lubricated condition using zinc oxide nanoparticles based mineral oil | B.Tech Mechanical | Shubrajit Bhaumik | 2014 |

| Tribological properties of carbon nano tubes based synthetic oil | B.Tech Mechanical | R.G Padmanabhan/Shubrajit Bhaumik | 2013 |

| Modeling and analysis of dry sliding wear using pin on disc tribometer | M.Tech- CAD | Shubrajit Bhaumik | 2016 |

| Numerical analysis of lubricated pin on disc experiment | M.Tech- CAD | Shubrajit Bhaumik | 2016 |

| Students Projects with Industry | |||

| Regeneration of chromic acid properties used in industrial hard chrome plating | B.Tech Mechanical | Mr.B. Rajesh – Sr. Engineer (R&D) India Pistons and Mr.Shubrajit Bhaumik, Assistant Professor (SRM University) | 2015 |

| Effect of time delay in carburizing on case depth | B.Tech Mechanical | Mr. Ganesh Prabhu – Sr. Metallurgy Engineer , India Pistons and Mr.Shubrajit Bhaumik, Assistant Professor (SRM University) | 2016 |

|

Ankur Dhanwant, B.Tech Mechanical Engineering (2015-2019)

I, Ankur Dhanwant (RA1511002010721, MECHANICAL) want to acknowledge and thank SRMIST, department of mechanical engineering, and the TSIRL (tribology and surface interaction research laboratory) for continuous support throughout my academics. I feel very happy and content to inform you that I have been placed in GABRIEL INDIA LIMITED (A flagship company of ANAND AUTOMOTIVE) in HOSUR, Tamil Nadu. I would extend my hearty thanks to the placement department, the CDC department and the all the authorities and department concerned for giving me an opportunity to explore, choose and finally get placed in an esteemed firm. I find the contribution of TSIRL and Dr Shubrajit bhaumik sir (my project guide), very crucial in getting placed in the core company of my domain. I have been a part of the tribology lab for 1 year. It all started with a project based on SURFACE TEXTURING with a very meagre idea about tribology to engaging in one of the very distinct major projects to actually getting an academic interest and direction, the TSIRL has been a major contributor to my knowledge about friction and wear-related stuff. Bhaumik Sir has been more than a project guide, rather being a true mentor and a very good friend for all of us. Apart from the academics, the TSIRL and Bhaumik sir has been an actuator for my interest in tribology. I must say that the environment of our tribology lab is friendly, fun loving, academically engaging in true sense. I sincerely thank Bhaumik sir and my teammates who helped me academically and emotionally throughout my stay at SRMIST. I would like to address some key points related to the field of tribology and my project. During my internship at Gabriel, I worked extensively on friction, wear and lubrication which made me search and read many resources including books and online courses to understand the basics of this science. It took me time to gather all resources and understand the tribological science apart from working on the major project which was experimental based research. I felt the need for this very important subject of tribology in understanding my work at Gabriel. We know that most of the companies are achieving automation as a need for industry 4.0 revolutionary standards but the relative motion and different kinds of contacts between mating surface still exist in any kind of machinery. Thus understanding the contact mechanics and the science of friction and wear of materials and surfaces becomes an essential part of engineering. Tribology has been in use in all kinds of applications ranging from automotive components, aerospace, MEMS, nanotechnology, biomedical, manufacturing, maintenance and many more. Such an important subject consisting of the basics of fluid mechanics, solid mechanics and surface engineering has become a need of the hour. I personally have felt its need while working in the automotive industry. We as students are lucky to have a dedicated lab for tribology, which has been extensively used for many industrial projects from reputed firms of the nation and very few institutions have a dedicated tribology laboratory |

|

Sandeep Gudiwala, Research Intern-Ecole Centrale de Nantes France

“I have done the Scuffing Resistivity of spur gears under different lubricants under the guidance of Prof. Shubrajit Bhaumik for my UG Project in the year 2015. It gave a great exposure towards the applications of lubrications in real-life industries applications. The industry course with India Pistons LTD. is another great chance to witness the processes they undergo in the industries to improve the life of the pistons rings and other coating processes. During my Master’s thesis at Ecole Centrale de Nantes,France, I have engaged Tribology in my thesis where I will be studying the Tribology of Interaction between Glass fibers and Resin during the manufacturing processes like RTM, Infusion and Thermo-plasting. I am glad that the University is realizing the importance of Tribology and encouraging the students to gain knowledge in this field both theoretically and practically.”- Sandeep Gudiwada (Regd. No. 1021110136 B.Tech, Mechanical Engineering, 2011-2015). |

|

Nishayan Ghosh, Jounior Engineer, Vicat Cement India Ltd.

“Tribology in Cement Industry is a vast subject and I am happy to apply the knowledge I gained while studying especially in open Gears lubrication systems”. |

|

Abhishek Kumar, Engine Cadet Anglo Eastern Shipping Management

“First of all I would like to thank SRM Institute of Science and Technology for giving me a chance to be a part of, it has so many reasons. In third year I took Industrial Tribology as my elective where I met Prof. Shubrajit Bhaumik, who later in final year became mentor for me. I cannot write in words the exposure I received from this course. It’s a industry oriented subject and is now helping me in my career. I am with a shipping company where Tribology has many applications. We can’t run engine even a second without lubrication. This is where my knowledge on Tribology has set me apart from the other fresh engineers who have joined with me. My final year project which was on Lubrication has helped me in understanding the Science behind lubrication technology. It was all because of Shubrajit sir who was able to ignite the I wish our Laboratory to be more successful in coming years and personally I will ever remain thankful to Prof. Bhaumik for planting the seed of interest for Tribology in me “- Abhishek Kumar (Regd. No.: 1021210240, B.Tech Mechanical Engineering, 2012-2016). |

|

Rishab Maggirwar , B.tech Mechanical Engineering,2014-2018.

“Prof. Shubrajit Bhaumik undertook me as his apprentice in my third year and since then I have been involved in an overwhelming depth of research in the field of Industrial Tribology. His indispensable counsel steered me into this niche field and never have I been more privileged to gain a hands – on experience with the equipment and facilities in the Surface Interaction Laboratory. I had the chance of being a part of several research projects over the years which helped me gain theoretical as well as practical knowledge in the field as Bhaumik Sir never thought twice to funnel important projects and initiatives in my direction. Without his trust in my abilities, it was nearly impossible for me to showcase my talents and achieve what I could in all of these years of my engineering. I am forever grateful for the support and guidance. Working in the lab has always been exciting and joyful and many a times many of our team mates do not even understand about the time. I wish our lab to be one of the renowned one and I am sure under the able leadership of our Tribology group the day is not far when our lab will be the best of its kind”. |

|

Sahil Asif , B.Tech – Mechanical Engineering (2012-2016) MS Mechanical Engineering | New York University It gives me great pleasure, to share my research experience working in the Tribology Laboratory, SRM under the guidance of Prof.Shubrajit Bhaumik. I graduated from SRM in 2016 and am currently pursuing my Master’s Degree in Mechanical Engineering at New York University. I did my research work in the laboratory for about 1 year for my final term project. Choosing the field of tribology as my final term project was indeed a challenge as it was (and still is) an upcoming field and I knew that I would have to contribute a lot of my time for it. When we started our project we just had a small room with a pin-on-disk tribometer and honestly it felt very much congested. We never knew that in some weeks we would be shifted to a brand-new laboratory which positively uplifted our spirits. Working in the main Tribology Laboratory was indeed very much fun and a great involvement. Being surrounded by all the machines and chemicals never made us deviate from our objective. Weather it was sample preparation, performing calculations on the white board, setting up the machine for testing or just scanning images, we all believed that if we would ever achieve what we wanted from our research, this lab would make it happen. We never felt tired in the laboratory even though we spent 8-10 hours continuously for our experiments. We used to enjoy the environment so much that spending almost half a day never seemed to be useless. As a matter of fact, we also unboxed and inaugurated the Four Ball Tester Machine which is currently there in the lab. It’s perfect working environment, and its setup makes it an ideal place for research oriented students. As from my personal experience, working on different instruments like Pin-On-Disk Tribometer, Four Ball Tester etc. has given me a perfect exposure in the field of tribology. In fact, we also presented a paper which was recognized by Anna University at the International Conference on Material, Manufacturing and Design as one of the 133 papers to be presented in the conference and published in their prospectus. The experience from working in the field of tribology has helped me a lot and it never stopped there at the conference. I am a Graduate Assistant and Teaching Assistant for Mechanical Department here at NYU, & also currently working on 2 major projects under the field of materials, I can easily say that my experience in tribology is playing a major role in it, as the knowledge of surface engineering gained during my days in our Tribology Laboratory at SRM University is helping me in various aspects of the projects. Last but not least, no doubt the lab is a tribology center and helps you get into the field, nothing would have been possible without the guidance of my Professor, Prof. Shubrajit Bhaumik. His polite & motivating nature, and his encouraging personality has taught me so much and indeed guided me to where I am today. I am sure under his able leadership this laboratory will produce eminent tribologists very soon. |

Profile

We provide tribological solutions to various engineering applications. Our areas of research include nano tribology, polymer tribology, bio tribology, green tribology and coatings for low friction and wear resistance.

Contact Person

Mr. J. Daniel Glad Stephen

Assistant Professor, Faculty in charge

stephenj@srmist.edu.in

Tribology and Surface Interaction Research Laboratory, MEHA 103C- Mechanical Engineering Hangar, Department of Mechanical Engineering, SRM Institute of Science and Technology, Kattankulathur, Chengalpattu District, Potheri, Tamil Nadu-603203.