Robotics Lab

Robotics Lab

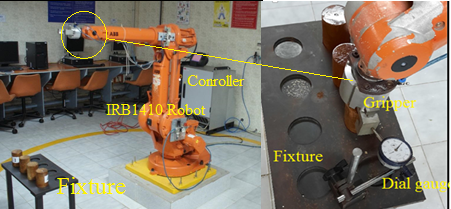

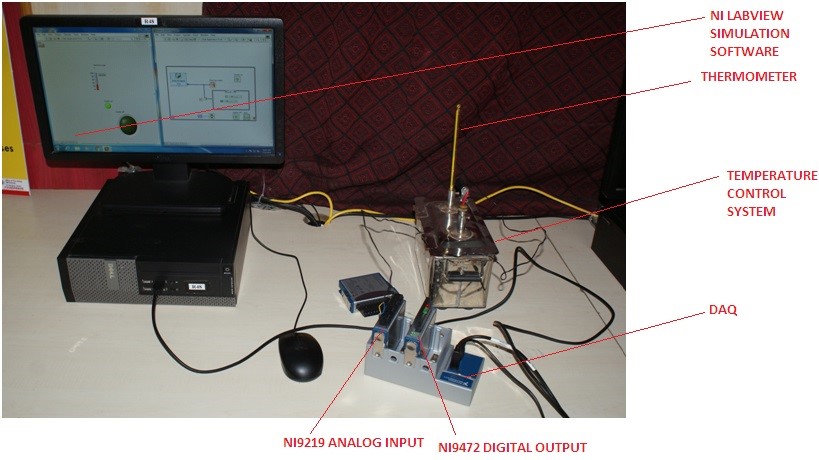

The Robotics lab of department of Mechanical Engineering, SRMIST was established in the year 2007 to conduct M.Tech robotics programme and B.Tech Mechanical engineering programme. It makes the students to understand the basic principle of robotics with the help of Lego Mindstorm kits and they explore the world of industrial robotics with the hands on experience using ABB IRB1410 6 axis Industrial robot, ABB IRB360 Flexpicker vision robot along with its simulation software namely RobotStudio 2020 and they are also able to design and program the mobile robots with our latest microcontroller trainer kit namely raspberry pi , Beagle bone, Arudino uno, ARM processors and they also learn to integrate I/O with DAQ and control the robot using Virtual Instrumentation hardware and software NI LabVIEW with different types of sensors like touch, proximity, light ,sound sensors, force, accelerometer gyroscope and load cell.

Specifications

- PROGRAMMING IRB1410 ROBOT (SERIAL MANIPULATOR) FOR PICK AND PLACING OPERATION BOTH IN MANUAL AND AUTOMATIC MODE

- PROGRAMMING IRB1410 ROBOT (SERIAL MANIPULATOR) TO HANDLE INPUT AND OUTPUT MODULES USING SUBROUTINES

- SIMULATING IRB1410 ROBOT FOR MACHINING OPERATIONS WITH DIFFERENT WORK CELL LAYOUT USING VIRTUAL FLEXPENDANT IN ROBOT STUDIO

- PROGRAMMING IRB360 VISION BASED FLEXPICKER ROBOT (PARALLEL MANIPULATOR) FOR PALLETISING OPERATIONS BASED ON COLOUR, SHAPE, DIMENSIONS AND ORIENTATION OF AN OBJECT

- A PLUG-IN MULTIFUNCTION DATA ACQUISITION (DAQ) DEVICE CONNECTED TO A TEMPERATURE SENSOR J TYPE THERMOCOUPLE FOR THE MEASUREMENT OF TEMPERATURE ATTACHED TO THE END EFFECTOR (TOOLS) OF THE ROBOT FOR THE AUTOMATIC CONTROL OF COOLANT MOTOR USING LABVIEW SIMULATOR.

- A MYRIO STUDENT EMBEDDED DEVICE CONNECTED TO A ACCELEROMETER FOR THE MEASUREMENT OF VIBRATION ATTACHED TO THE END EFFECTOR OF THE ROBOT IS ANALYSED USING LABVIEW

- BUILD A CONTROL SYSTEM FOR A MOBILE ROBOT USING ARDUINO WITH SENSORS FOR OBSTACLE DETECTION SYSTEMS

- DEVICE A BLUETOOTH COMMUNICATION BASED QUADPOD ROBOT FOR MULTI-TERRAIN ENVIRONMENT

- IMPLEMENTATION OF IOT BASED ELECTRICAL CIRCUITS FOR FACTORY AUTOMATIONS.

- IMPLEMENTATION OF MACHINE LEARNING BASED IMAGE SEGMENTATION ANALYSIS USING RASPBERRY PI

| Sl.No. | Equipment/Instrument | Specification details |

| 1. | ABB IRB 1410 | Robot supplier – ABB, China, Robot Version – IRB 1410, Robot controller – IRC5, Handling capacity – 5kg, Reach – 1.45m, manipulator weight – 225kg, No of axis – 6 |

| 2. | ABB IRB 360 | Robot supplier – ABB, Bangalore, Robot Version – IRB 360, Robot controller – IRC5, Handling capacity – 3kg, Reach – 1.13m, No of DOF – 6, Vision colour camera – Basler Scout-scA1300-32gc |

| 3. | NI cDAQ-9174 | 4‑Slot, USB communication Compact DAQ Chassis, Supports more than 60 sensor-specific I/O modules with integrated signal conditioning, Four general-purpose 32-bit counter/timers built into chassis, Run up to 7 hardware-timed analog I/O, digital I/O, or counter/timer operations simultaneously |

| 4. | NI 9219 | 4 AI, 100 S/s/ch Simultaneous, Universal Measurements, Spring-terminal connectivity, Support for Thermocouple (50 S/s/ch), RTD, Resistance, Full-Bridge, Half-Bridge, Quarter-Bridge, Voltage, and Current Measurements, Voltage and current excitation, 250 VAC, CAT II, channel-to-channel isolation |

| 5. | NI 9263 | 4 AO, ±10 V, 16 Bit, 100 kS/s/ch Simultaneous, Screw-terminal or spring-terminal connectivity, 250 Vrms, CAT II, channel-to-earth isolation |

| 6. | NI 9421 | 8-Channel Sinking Digital Input Module, 8-channel, 100 µs digital input, 24 V logic, sinking digital input, Compatible with NI CompactDAQ counters, 60 VDC, CAT I (DSUB) or 250 Vrms, CAT II (screw and spring terminal) isolation, 25-pin DSUB, 10-position spring-terminal, or 10-position screw-terminal connectors available, -40 °C to 70 °C operating, 5 g vibration, 50 g shock |

| 7. | NI 9472 | 8 DO, 6 V to 30 V, Sourcing, 100 μs, DSUB, screw-terminal, or spring-terminal, connectivity, CompactDAQ counter compatibility, 250 Vrms, CAT II, channel-to-earth isolation, (screw and spring terminal); 60 VDC, CAT I, channel-to-earth isolation (DSUB) |

| 8. | NI myRIO | Xilinx Z-7010 processor 667 MHz (ARM Cortex A9 x2 cores 28 nm process NEON SIMD, VFPv3 Vector Float), Memory: NV: 256 MB, DDR3 512MB, 533 MHz, 16 bits, FPGA type same as processor, Wireless: IEEE 802.11 b,g,n ISM 2.4 GHz 20 MHz., USB 2.0 Hi-Speed, Breakout Board support, 2 ports of 16 Digital I/O lines, 3 axis accelerometer, Max power consumption : 14 W, Typical idle : 2.6 W, LED’s |

| 9. | Arduino uno | Microcontroller – ATmega328P, Operating Voltage – 5V, Input Voltage – 7-12V, Input Voltage – 6-20V, Digital I/O Pins – 14 (of which 6 provide PWM output), PWM Digital I/O Pins – 6, Analog Input Pins – 6, DC Current per I/O Pin – 20 mA, DC Current for 3.3V Pin – 50 mA, Flash Memory – 32 KB (ATmega328P) of which 0.5 KB used by boot loader, SRAM – 2 KB (ATmega328P), EEPROM – 1 KB (ATmega328P), Clock Speed – 16 MHz, LED_BUILTIN – 13, Length – 68.6 mm, Width – 53.4 mm, Weight – 25 g. |

| 10. | Raspberry Pi 2 | Broadcom BCM2837 Arm7 Quad Core Processor powered Single Board Computer running at 900MHz, 1GB RAM, 40pin extended GPIO, 4 x USB 2 ports, 4 pole Stereo output and Composite video port, Full size HDMI, CSI camera port for connecting the Raspberry Pi camera, DSI display port for connecting the Raspberry Pi touch screen display, Micro SD port for loading your operating system and storing data, Micro USB power source |

| 11. | Beagle bone | Processor: AM335x 1GHz ARM® Cortex-A8, 512MB DDR3 RAM, 4GB 8-bit eMMC on-board, flash storage, 3D graphics accelerator, NEON floating-point accelerator, 2x PRU 32-bit microcontrollers |

IRB1410 is a well-proven and cost-efficient six axis robot with a stroke and reach sufficient for most arc welding, pick and place, painting applications in industries, and currently most of the industries are moving to robotics technology where engineers are required to handle those robots and we teach the students to handle and program the robot using RAPID language in both offline and in simulation.

ABB’s IRB360 FlexPicker has been the leader in state-of-the-art high speed robotic picking and packing technology. It’s an parallel manipulator robot and has patent of world fastest pick and place robot using machine vision and its major application finds in food packaging Industries.

To acquire extramural knowledge on the computer implementation and i/o hardware interfacing of Robotics system with the external world were achieved using National instruments Virtual Instrumentation kit using both hardware and software

The foundation education in electronic circuit analysis and design the system was made using various latest microcontroller namely raspberry pi, beagle bone, arm processor trainer kit, 8051 trainer kit, PID based servo motor control kit and all basic electronic components.

Profile

This laboratory is a unique collaboration that harnesses the collective strengths of its Institution partners, and brings together the best expertise from industry and the academic community in modern and industrial Robotics. Students understand the basic concepts and principles related robots and they explore industrial robotics with ABB IRB 1410 6 axial Industrial robot, ABB IRB 360 Flexi picker robot along with its online control software Robot studio V 6.0 and they will be able to design and program the mobile robots with our latest microcontroller trainer kits: Raspberry pi, Beagle bone, Arduino uno, ARM processors. They also learn to integrate I/O with DAC and control the Robot using Virtual Instrumentation hardware and software NI LabVIEW with different types of sensors like touch, proximity, light, sound sensors, force, accelerometer gyroscope and load cell to measure various parameters related to robotics and their control.