360 Degree Lab View

<

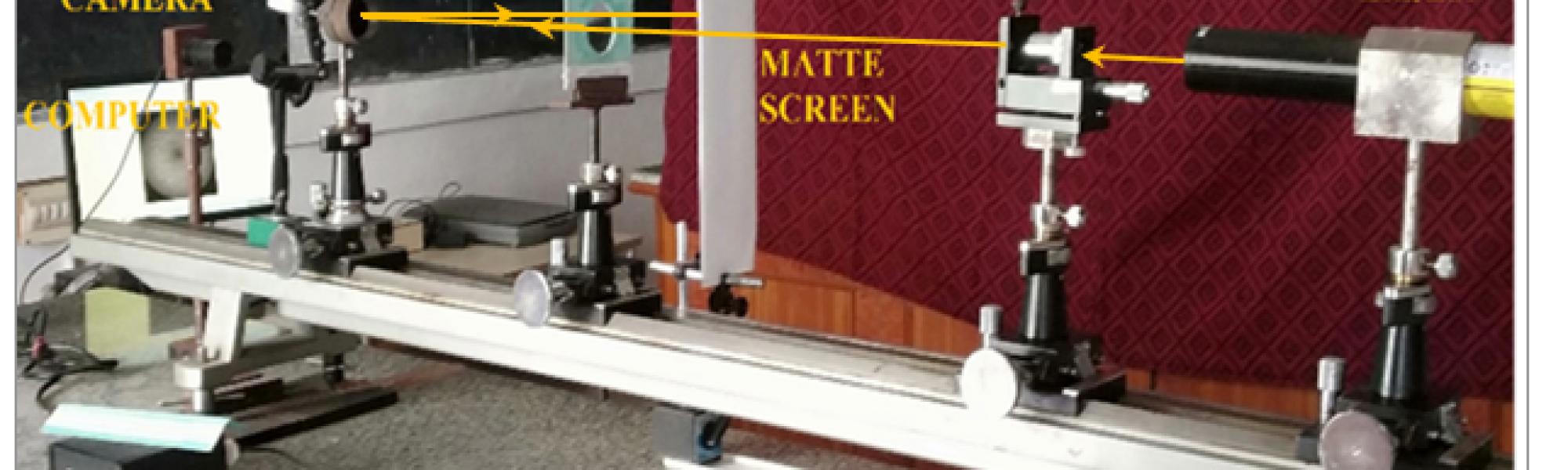

Metrology, the science of measurement, helps manufacturers to attain the proper fit and finish for their products. It embraces with selection of measuring instruments, methodology of measurements, standard of measurements with an experimental measurements and the determinations of uncertainty involved in geometric, form and position measurements. Metrology Lab plays a crucial role for a student who wants to pursue his career in industrial engineering and shop floor control. Metrology lab’s list of experiment are chosen in such a way to familiarize our B. Tech pre- final year students in various kinds of measuring tools/instruments, measuring techniques, measurement methods, calibration procedures with familiarity in SQC concepts. The laboratory experiments includes calibration of small instruments, taper angle, thread , gear parameter measurements with modern key equipment’s like computerized profile projector, Tool makers microscope and a machine vision system. The computerized surface roughness tester is used for improving the students understanding towards the analysis of roughness parameters and its significance.

test

Metrology Lab plays a crucial role for a student who wants to pursue his career in industrial engineering and shop floor control. Metrology lab’s list of experiment are chosen in such a way to familiarize our B. Tech final year students in various kinds of measuring tools/instruments, measuring techniques, measurement methods, calibration procedures, SQC procedures. The students learn the measurement procedure in basic measuring instruments such as thread micrometer, gear tooth vernier, lever dial gauge, GO-NO gauges and centre distance gauge other than normal micrometer and vernier calliper used in shop floor. The calibration exercise makes them to find the standard error involved in the measuring instrument using set of slip gauges