Mass Transfer Laboratory

- Home

- Faculty of Engineering & Technology

- Department of Chemical Engineering

- Mass Transfer Laboratory

About the Lab

Chemical Engineering is concerned with modifying raw materials in individual or combined steps of physical, chemical, and biological ways to convert them into desired products. Some of the unit operations directly involved changing the compositions of the mixture to make them separate into individual components. Mostly these all are physical separations and are involved in the preparation of Raw material for the process, and the purification of products at the downstream operations to ensure the quality of the products. Based on the miscible or immiscible nature of phases solid-solid, solid-liquid, solid-gas, liquid-solid, liquid-liquid, liquid-gas, gas-solid, gas-liquid, and gas-gas can select the operations to separate the components of desire. Such operations are Adsorption, Absorption, distillation, decantation, diffusion, extraction, filtration, humidification, leaching, and so on.

The mass transfer Lab at SRMIST has both glass wares type of model set-up as well as for pilot scales like prototype equipment for learning and research purposes. Students Will Learn the fundamentals and can-do research in large-scale operations. and

The academic and research labs were equipped with all the novel equipment facilities. For membrane-based separations, the lab has a facility for hollow fiber membrane fabrication set-up, flat sheet membrane production, membrane distillation unit, and membrane testing kit.

Specifications

Practice 1: Vapour in air diffusion

Practice 2: Absorption

Practice 3: Batch Distillation

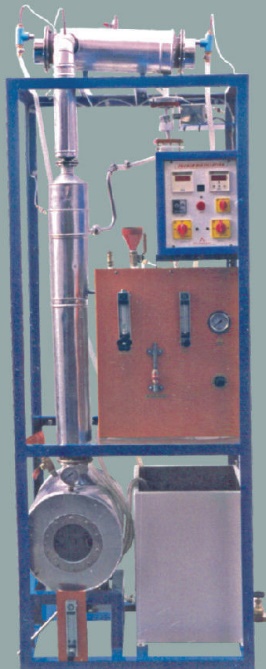

Practice 4: Steam Distillation

Practice 5: Sieve plate distillation column

Practice 6: Liquid – liquid extraction

Practice 7: Single stage extraction

Practice 8: Multi stage extraction

Practice 9: Soxhlet Extractor

Practice 10: Simple batch – Tray drier

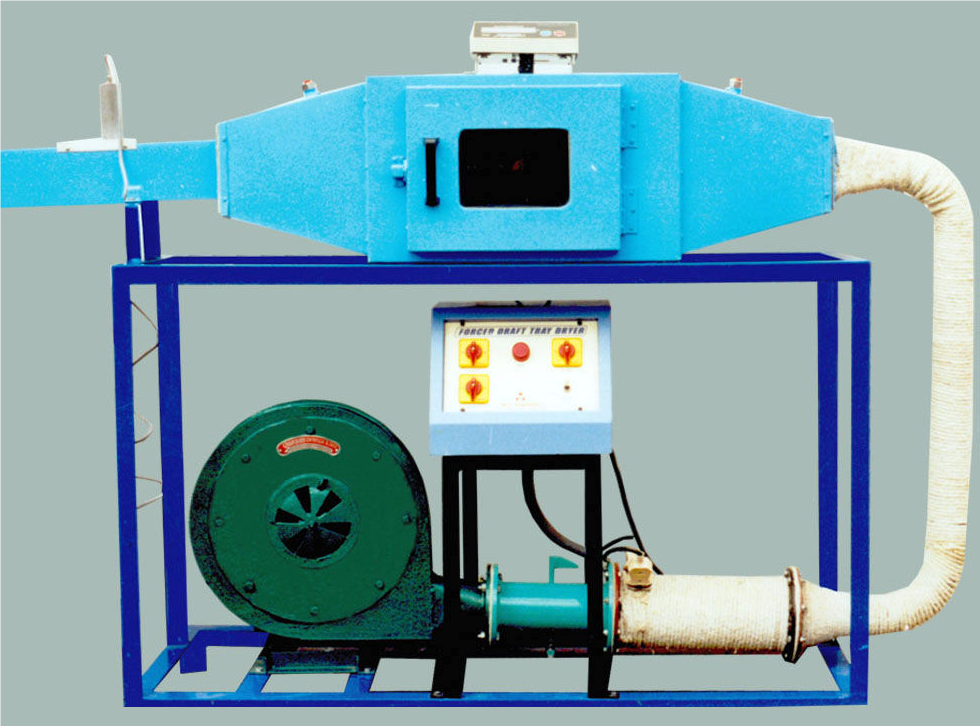

Practice 11: Forced draft tray dryer

Practice 12: Batch adsorption

Practice 13: Fixed bed adsorption

Practice 14: Distillation in Aspen Plus

Practice 15: LLE in Aspen Plus

Column made of SS, Dia. 80mm, Height 900mm (approx.), Packing Material : Borosilicate Glass Rasching Rings. Pressure Gauge : Bourdon type, Rotameter : For cooling water flow rate measurement. Steam Generator : Made of Stainless Steel, provided with Pressure Gauge & Level, Indicator, Safety valve & insulated with ceramic wool and cladding with Aluminium foil. Reflux Divider : Arrangement to change R/D ratio automatically.Condenser : Material Stainless Steel, Shell & Tube type, Bottom Product Tank : Material Stainless Steel capacity 5 Ltrs. Distillate tank : Material Stainless Steel, capacity 5 Ltrs. Temp. Sensors : RTD PT-100 type, digital Temp. Controller : PID Controller, 0-199.9°C, (For Re-boiler), Digital Temp. Indicator : 0-199.9°C, with multi-channel switch, Reflux timer : For changing R/D ratio

Column made of SS, Dia. 80mm, Height 900mm (approx.), Packing Material : Borosilicate Glass Rasching Rings. Pressure Gauge : Bourdon type, Rotameter : For cooling water flow rate measurement. Steam Generator : Made of Stainless Steel, provided with Pressure Gauge & Level, Indicator, Safety valve & insulated with ceramic wool and cladding with Aluminium foil. Reflux Divider : Arrangement to change R/D ratio automatically.Condenser : Material Stainless Steel, Shell & Tube type, Bottom Product Tank : Material Stainless Steel capacity 5 Ltrs. Distillate tank : Material Stainless Steel, capacity 5 Ltrs. Temp. Sensors : RTD PT-100 type, digital Temp. Controller : PID Controller, 0-199.9°C, (For Re-boiler), Digital Temp. Indicator : 0-199.9°C, with multi-channel switch, Reflux timer : For changing R/D ratio

Drying Chamber : Insulated double wall chamber, Size (20 x 20 x 25) cm, Weighing Balance : Digital (0-1000gm) of ± 1 gm resolution. Hot Air Circulation : By forced draft fan, Arrangement is done to vary the air flow rate. Heating Chamber : Compatible capacity. Heater : Nichrome wire heater. Temperature Sensors : RTD PT – 100 Type, Control panel comprises of : Digital Temp. Controller : PID Controller, 0-199.9° C, Digital Temp. Indicator : 0-199.9° C (with multi-channel switch)

Column (3 Nos.) : Material Borosilicate glass of different dia., Feed tank : Material Stainless Steel, Capacity 20 litres, Receiving tank : Material Stainless Steel (3 Nos.), Capacity 5 litres. (For all 3 columns), Feed circulation : FHP, Magnetic Pump made of Polypropylene. Piping : Stainless Steel and PVC of size ¼″, Flow measurement : Rotameter for feed, Stop Watch : Electronic.

Extraction Column : Material Borosilicate Glass, Dia 80 mm, Height 500 mm (approx.), Solvent Flow Measurement: By Rotameter., Solvent Tank : Made of Stainless Steel, Capacity 30 Ltrs. Double walled, Solvent circulation : By Magnetic Pump, made of Polypropylene for solvent, Maximum working temperature 60°C, Heater : Nichrome wire heater, Receiving Tank : Material Stainless Steel, Compatible capacity with sieve, Temperature Sensor : RTD PT-100 Type, Control panel comprising of: Digital Temp. Controller : PID Controller, 0-199.9°C (For Feed Tank)

Tower : Material Stainless Steel, Size: Cross-Section (150x150) mm,Height 750 mm, Packing : Expanded wire mesh, Air Circulation : By forced draft fan, arrangement is done to vary air flow rate, Air Flow Measurement : Orifice meter with U-tube manometer, Water Flow Measurement : By Rotameter, Dry & Wet Bulb Temp. : Measured by Temperature Sensors, Hot Water Tank : Material Stainless Steel, Double wall, insulated with ceramic fibre wool, Hot water circulation : Magnetic Pump, Heater : Nichrome wire heater, Temperature sensors : RTD PT-100 type, 6 Nos, Control panel comprising of : Digital Temp. Controller : PID Controller, 0-199.9°C, (For hot water tank), Digital Temp. Indicator : 0-199.9°C, with multi-channel switch

Crystallizer : Jacketed Type, Material Stainless, Steel, Cap. 2 Ltrs. With conical bottom, Stirrer : FHP, Variable Speed, Heater : Nichrome wire heater, Cooling Water Tank : Material Stainless Steel, Capacity, 30 litre fitted with Pump, Flow measurement : By Rotameter for cooling water, Pump : FHP, Receiving Tank : Material Stainless Steel, Capacity 2 litre with SS sieve, Temp. Sensors : RTD PT-100 type, Control panel comprises of : Digital Temp. Indicator : 0-199.9ºC with multi-channel switch.

Tube : Material Borosilicate Glass, Water Bath : Material Stainless Steel with two sides made of glass Capacity 8 Ltrs, Fitted with heater and stirrer, Heater : Nichrome Wire Heater, Stirrer : Stainless Steel, Impeller and shaft coupled with FHP motor, Air Circulation : By Air Pump, Traveling Microscope : 0-150 x 0.1 mm resolution, Temp. Sensor : RTD PT-100 type, Control panel comprising of : Digital Temp. Controller: PID Controller, 0-199.9°C cum-Indicator (For Water Bath

Column : Material Stainless Steel, Dia 80mm, Length 1000mm (approx.), One section of column is provided of Borosilicate glass to visualize the process, Plates : Perforated Plates, Material Stainless Steel (7Nos.), Feed Circulation : By compressed air, Pressure Regulator : 0-2 kg/cm², Pressure Gauge : Bourdon type, Feed Tank : Material Stainless Steel, Capacity 20 Ltrs. (approx.), Flow Measurement : Rotameters (One each for feed, air & CO2), Collecting Tank : Material Stainless Steel, Capacity 10 Ltrs.

Distillation Vessel : Material Stainless Steel, Capacity 3 Ltrs. (approx.), Jacketed Type, insulated with ceramic wool and Aluminium cladding, Flow measurement : Rotameter for cold water, Steam Generator : Made of Stainless Steel, provided with Pressure Gauge & Level Indicator, Safety valve & insulated with ceramic wool and Aluminium cladding, Separating Chamber : Material Borosilicate Glass, Capacity 2 Ltrs. (approx.), Condenser : Material Stainless Steel, Shell & Tube type, Distillate tank : Material Stainless Steel, Capacity 5 Ltrs. (approx.), Heater : Nichrome wire heater, Temp. Sensors : RTD PT-100 type, Digital Temp. Controller : PID Controller, 0-199.9°C, (For Steam Generator), Digital Temp. Indicator : 0-199.9°C, with multi-channel switch

Extraction Column : Material Borosilicate Glass, Dia 55 mm, Height 750 mm (approx), Packing : Rasching Rings, Material Borosilicate Glass, Feed Tanks : Material Stainless Steel (2Nos.), Cap. 20 Ltrs, Extract & Raffinate Tanks : Material Stainless Steel (1each), Cap. 10 Ltrs., Feed Circulation : By Compressed Air, Flow Measurement : Rotameters-2Nos, (One each for solvent & solute), Pressure Regulator : 0-2 kg/cm2, Pressure Gauge : Bourdon type, 0-2 kg/cm2