Electrical Machines Laboratory

- Home

- Faculty of Engineering & Technology

- Department of Electrical and Electronics Engineering

- Electrical Machines Laboratory

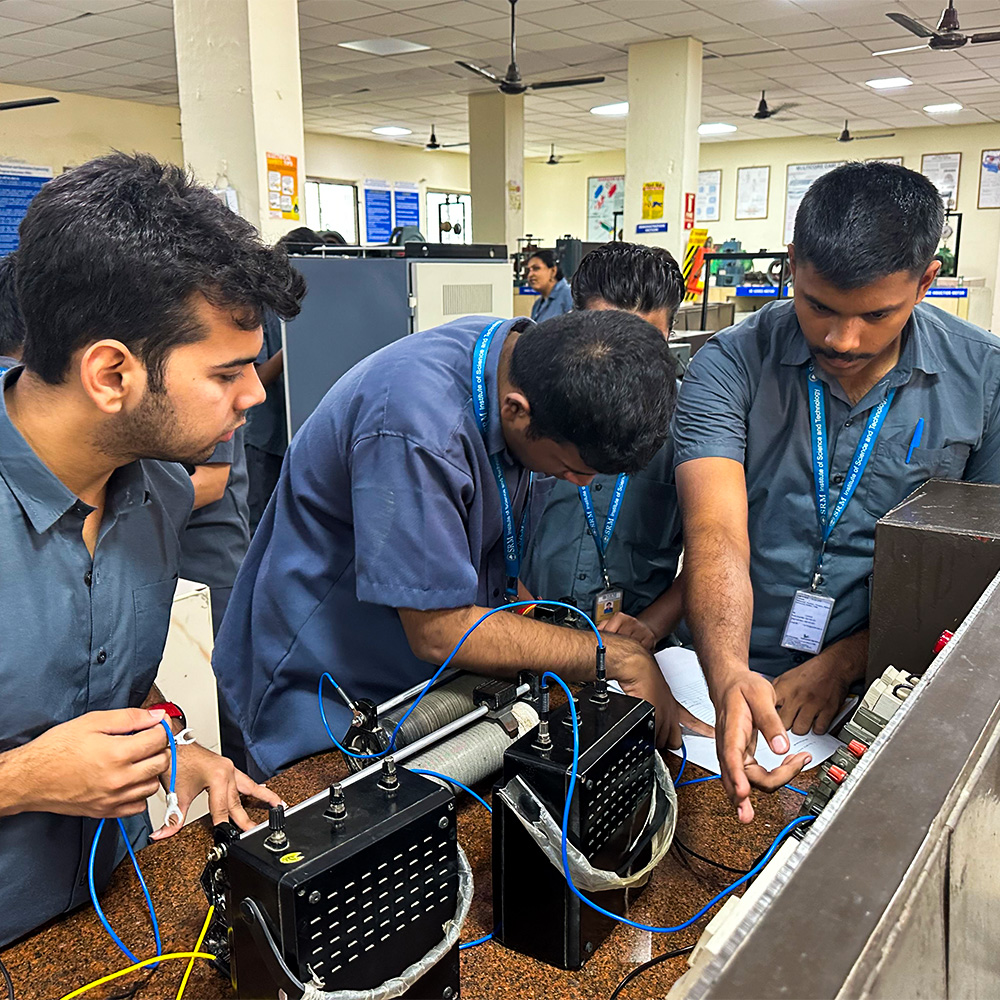

Electrical Machines Laboratory

The Electrical Machines Laboratory plays a crucial role in helping students bridge the gap between theoretical knowledge and practical application. It enables them to gain a deeper understanding of electrical machines and prepares them to face real-world challenges in the field of electrical engineering.

The laboratory is equipped with both conventional and modern electrical and electronic measuring instruments, a variety of transformers, and conventional as well as automated AC and DC electrical machines. It caters to the needs of undergraduate students, enabling them to grasp fundamental concepts and gradually adapt to advanced experiments, such as modeling electrical machines and working with special types of electrical machines. The laboratory also supports research activities using ALTAIR software and facilitates project work focused on the design of electrical machines.

Specifications

Utilization of the laboratory

The following equipment and components are currently available to support the conduction of experiments in the Electrical Machines Laboratory:

- Step-up and step-down transformers

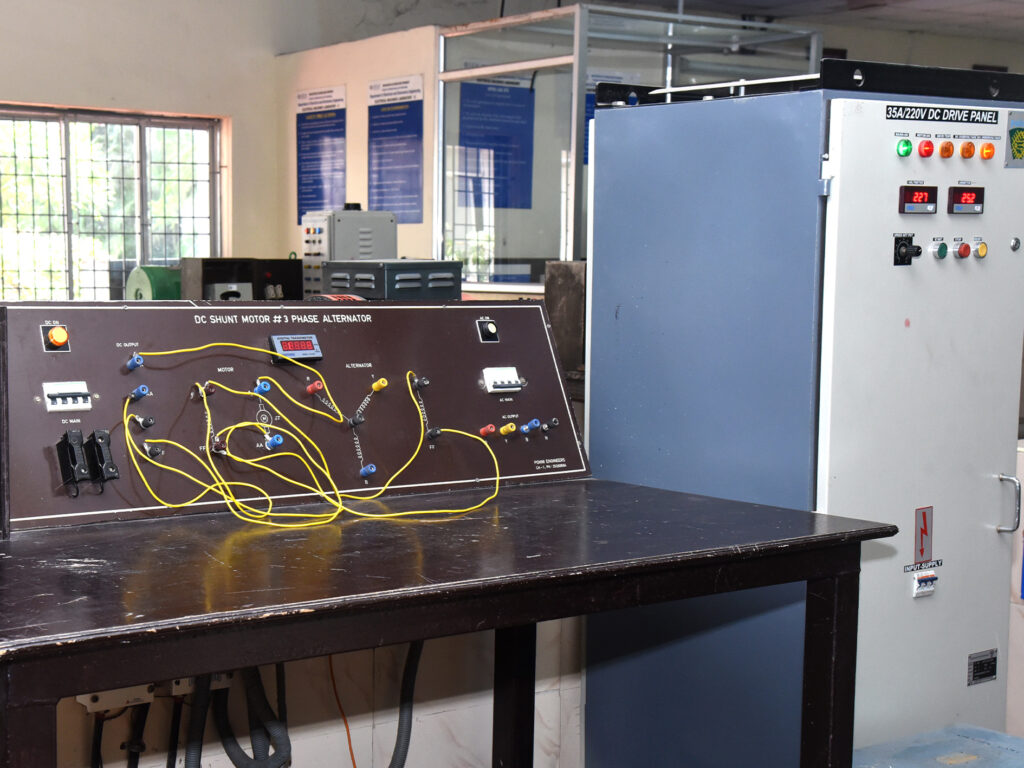

- Three-phase alternators coupled with DC motors

- Shunt motor coupled with a DC thyristor control panel

- Synchronous motor coupled with DC generators

- Three-phase squirrel cage induction motors

- Three-phase squirrel cage induction motors coupled with a DC shunt motor

- Single-phase squirrel cage, capacitor start, capacitor run induction motors

- Three-phase and single-phase auto transformers of various ratings

- Phase sequence indicator

- Various ratings and types of portable measuring equipment such as frequency meters, watt meters, voltmeters and ammeters

- Induction motor braking system

- Special electrical machines: SRM, PMBLDC

The laboratory is used for

- Academic Laboratory Sessions

-

- To conduct regular practical sessions for undergraduate courses such as Electrical Machines I, Electrical Machines II

- Supports curriculum-based experiments aligned with the SRMIST syllabus and learning outcomes.

- Project Work and Design Development

-

- Facilitates student projects related to the design, simulation, and fabrication of electrical machines.

- Supports final-year and mini-projects with experimental validation setups.

- Research and Innovation

- Enables research in electrical machine modeling, control techniques, and efficiency enhancement.

- Used by PG students and research scholars for simulation and analysis using ALTAIR software.

- Laboratory Enhancements and Automation

- Equipped for testing both conventional and modern machines, including lab-view based automation monitoring setups.

- Serves as a base for experimental development of smart machine systems.

No data was found

List of Major Equipment available

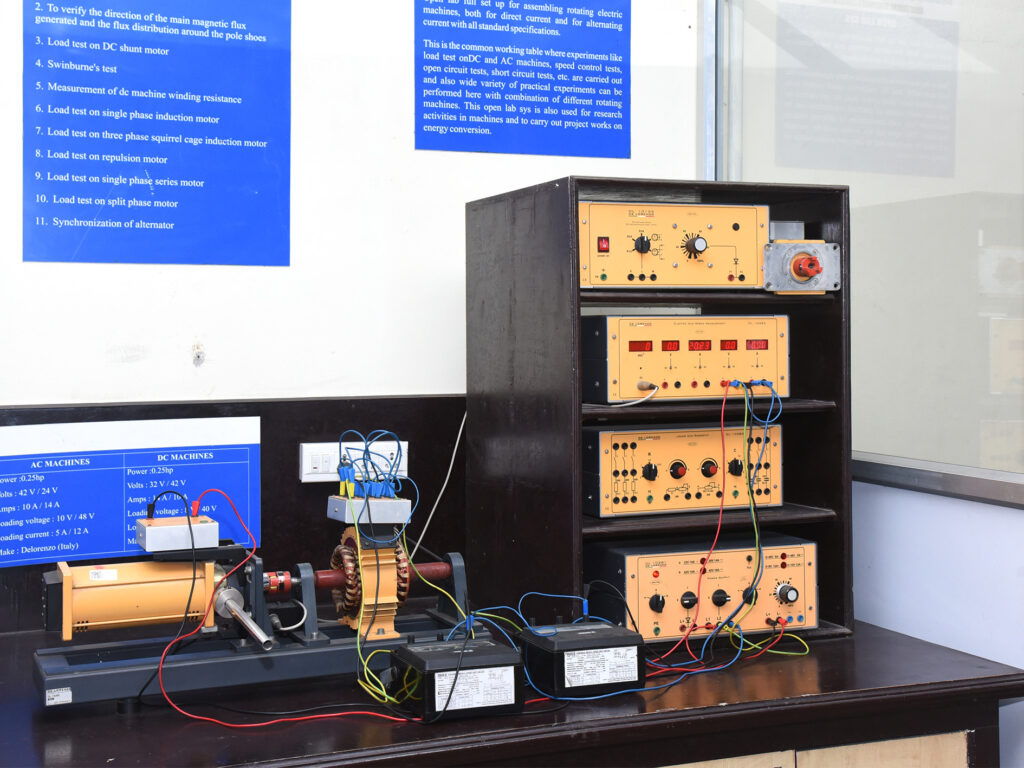

Open Lab System Type DC And AC Machines

This system is a complete set of components and modules suitable for assembling the rotating electric machine with can operate in both AC and DC supply. Students can perform a critical and well-analyzed assembly, in order to understand the production techniques before performing practical tests of the operating characteristics. The machines have fully industrial features with low-voltage specifications. Over 40 experiments can be performed which includes characteristics/load tests of various AC and DC machines.

Machine Automation Setup Using Lab view Based Simulation and Real-Time Data Acquisition and Control Using Crio Processor

The compact RIO-based NI embedded control platform gives an option to implement the PWM techniques for the inverters, DC-DC converters, special machine control etc. The LabVIEW-based graphical programming environment provides an intuitive method for students to acquire, visualize and process the signal from the experiment setup.

DC Shunt Motor Coupled KEC Alternator with DC Thyristor Controller

The setup has a coupling of the DC shunt motor to the KEC alternator and uses a DC thyristor controller to control the speed of the DC shunt motor. This setup could be utilized in applications where a constant speed is required, and the output of the KEC alternator needs to be regulated based on the motor's speed. In addition, FPGA and DSP processors-based motor control setup is deployed to study the various characteristics of the electric drive.

Thrust Research Areas

- Modeling and Simulation of Electrical Machines: Using tools like ALTAIR and MATLAB for design and analysis.

- Electric Vehicle Applications: Motor design and control for traction and regenerative systems.

- Energy Efficiency and Loss Reduction: Optimization of machine performance and thermal management.

- Condition Monitoring and Fault Diagnosis: Predictive maintenance using sensors and data analysis.

No data was found

No data was found

No data was found

No data was found

Contact Persons

Dr. V. Pradeep

Assistant Professor

pradeepv@srmist.edu.in

Mr. V. Rajeev Gandhi

Technician

rajeevgv@srmist.edu.in

Mr. R. Mahendran

Technician

Mahendr@srmist.edu.in

No data was found

Location: Electrical Science Block (ESB), ESB-103

Open Door Access : 9.00 am - 5.00 pm