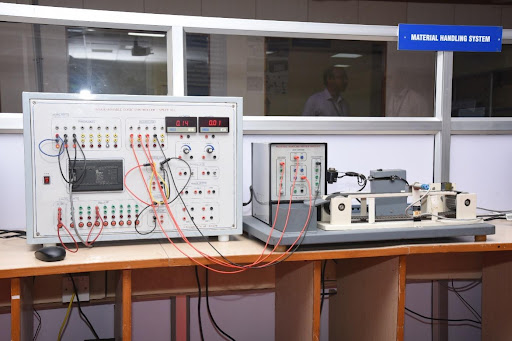

Automation Lab

Automation lab

Automation laboratory is one of the well-equipped core laboratory in Electronics and Instrumentation department. It has Programmable Logic controller and SCADA (Supervisory Control and Data Acquisition system) to control as well as monitor the process automatically.

Programmable logic controllers are now the most widely used industrial process control technology. A programmable logic controller (PLC) is an industrial grade computer that is capable of being programmed to perform control functions. The programmable controller has eliminated much of the hardwiring associated with conventional relay control circuits. Other benefits include fast response, easy programming and installation, high control speed, network compatibility, troubleshooting and testing convenience, and high reliability. The PLC is designed for multiple input and output arrangements, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact.

Specifications

- Siemens PLC – 3 Nos.

- GE FanucPLC – 7 Nos.

- Mitsubishi PLC – 3 Nos.

- Material Handling System

- Bottle Filling System

- Level Control System

- DC Motor Speed Control System

- Automatic Carparking System

- Lift Control System

- Star Delta Starter

- Temperature Control System

- Stamping Machine

- Electro Pneumatic Trainer

- Flow Control System

- Temperature Control System

- SCADA Software.

- Johnson Controls – Field Equipment Controller(Building Automation)

Material Handling System

Bottle Filling System

Level Control System

Flow Control System

Lift Control System

Stamping Machine

Temperature Control System

Johnson Controls – Field Equipment Controller

Lab in Charge

Dr. J. Sam Jeba Kumar

Assistant Professor, Department of EIE

9443170705

jebajumj@srmist.edu.in

R. Sampath Narayanan

Technical Assistant

sampathr@srmist.edu.in

H518, 5th floor Hitech block